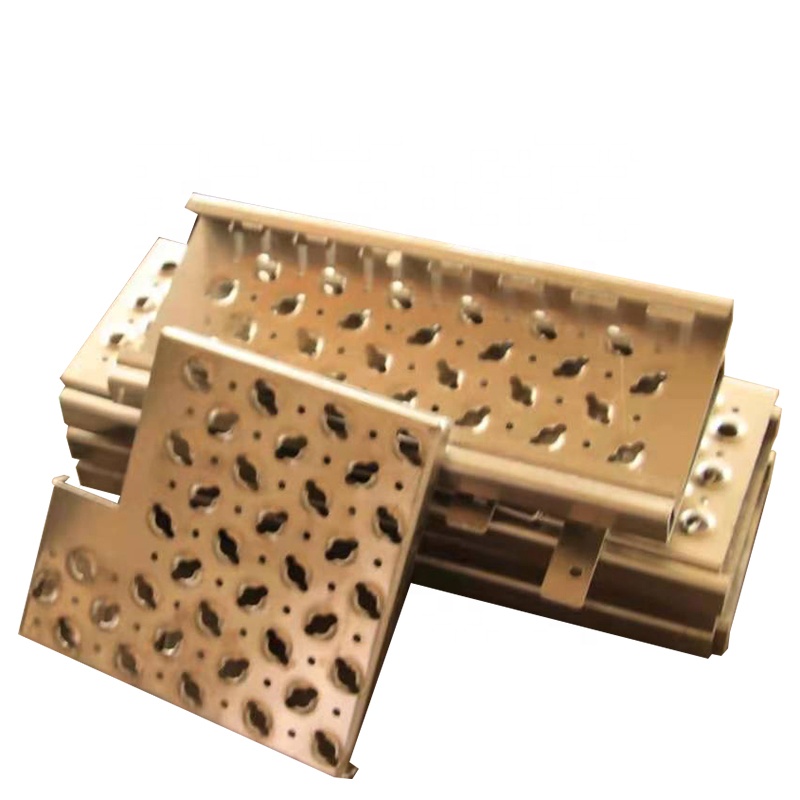

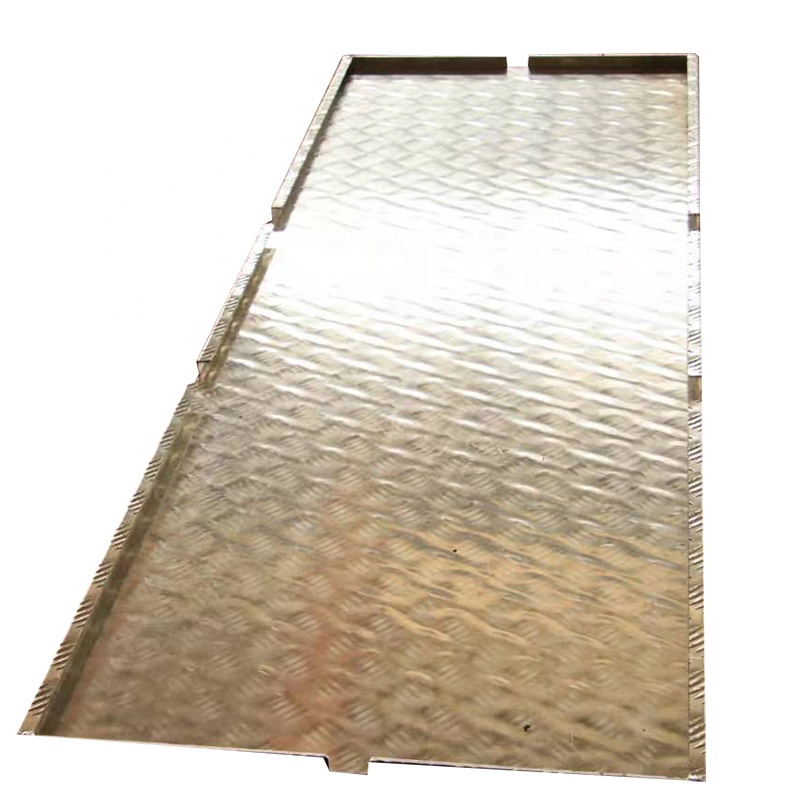

Likarolo tsa tšepe tse entsoeng ka tšepe tse entsoeng ka motsoako oa aluminium

Li-Paramenters tsa Lihlahisoa

| Tshebeletso | Mochini oa CNC |

| Lebokose la Taolo | |

| Tšebeletso ea ho khaola Laser | |

| Bracket ea tšepe | |

| Likarolo tsa Setempe | |

| Lintho tse bonahalang | *Aluminium |

| *Tšepe,Tšepe e se nang tšepe | |

| * Koporo, Koporo | |

| *Polasetiki | |

| * Die Casting | |

| Qetella | Ho phatloha ha lehlabathe, 'Mala oa Anodizing, Ho fifala, Zinc\Nickl Plating, Ho bentša le ho Brushing, joalo-joalo. |

| Thepa e ka Sehloohong | CNC Machining Center(Milling), CNC Lathe, Griantry CNC Machining Center, Etc. |

| Mochini oa Silinda oa Cylindrical, Mochini oa ho Epa, Mochini o Sehang oa Laser, jj. | |

| Mochini o Kobehang, Mochini o Temang, Mochini o Felisang Lehlabathe, Mohala oa Powder Coating. | |

| Tube Laser Cutting Machine, Flame Cutting Machine, Robert Welding Arm, Etc. | |

| Sebopeho sa ho taka | Mohato, Stp, Gis, Cad, Pdf, Dwg, Dxf Etc Kapa Mehlala. |

| Nako ea thomello | Matsatsi a 5-30 a itšetlehile ka bongata |

| QC | ROSH, CE, ISO |

| Mamello | +/-0.02mm ~ +/-0.05mm |

| Bokhopo ba Sekaho | Ra 0.6-3.2 |

Sehlopha sa Lihlahisoa

Matla a Khampani

LBH

Ngola molaetsa wa hao mona mme o re romele wona