Hnyav Loj Hlau Fabrication Vuam thiab Fabrication

Cov ntaub ntawv khoom

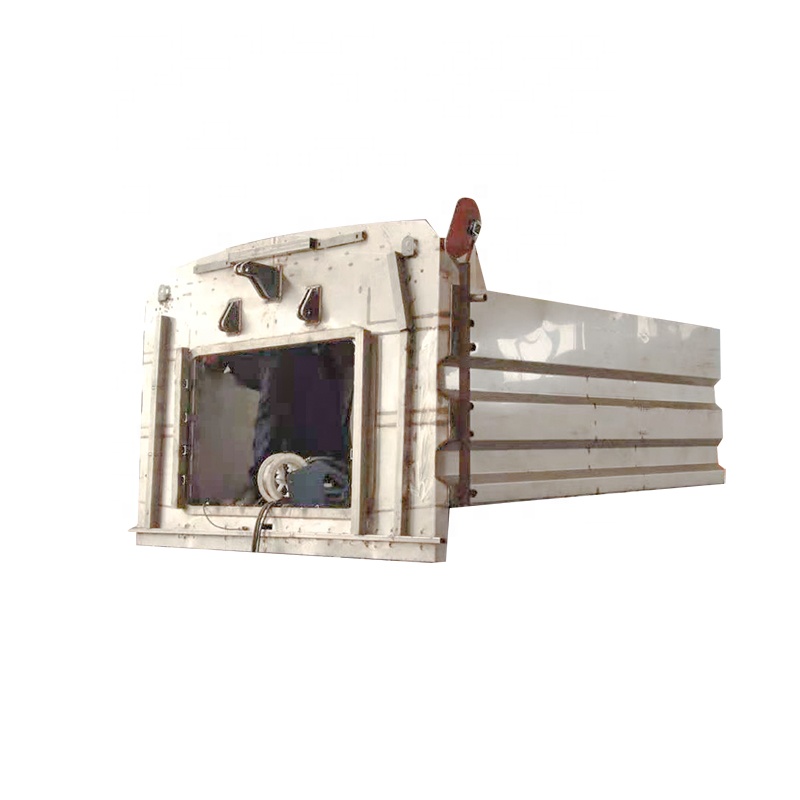

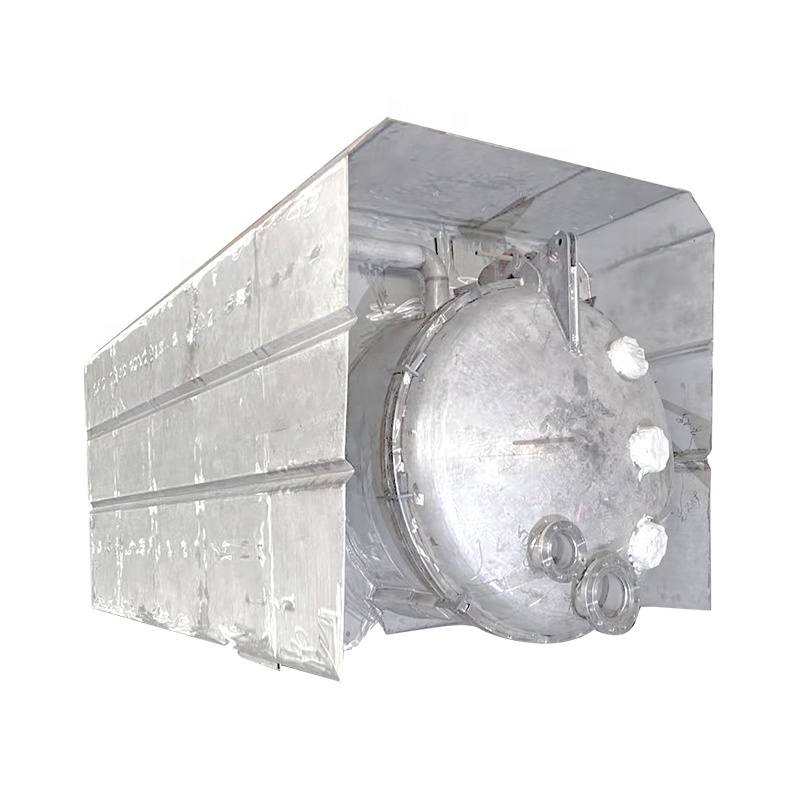

Peb muaj kev nplua nuj nyob hauv kev tsim cov boilers thiab lwm cov ntim loj, thiab muaj cov txheej txheem tsim khoom tshiab thiab cov tswv yim, uas tuaj yeem muab txhua yam khoom koj xav tau

Modular Boiler Systems yog tsim los ntawm ntau chav nyob uas ua haujlwm ua ke ua ib qho los tswj cov chav dej hla ntau lub boilers.

Qhov kev ua tau zoo, ntawm qhov xav tau chav ua haujlwm sai sai tig boilers ON thiab OFF kom phim cov kev xav tau ntawm chav dej.Tig lub boilers OFF thaum tsis siv tuaj yeem ua rau 20% txo qis hauv kev siv roj, txo qis tso zis, thiab tsawg dua txhua lub sijhawm.Ntxiv rau, cov boilers no tsis tas yuav hlawv roj khib nyiab hauv lub xeev tsis muaj zog thaum tsis siv.

Modular designs ua rau lub siab tawv hauv qhov system scalability.Ntxiv units raws li kev tsim khoom nce, thiab kaw cov chav yog tias qhov kev thov txo qis vim muaj kev hloov pauv lossis kev tso tseg tam sim ntawd tso cai rau kev hloov pauv mus rau lub sijhawm tsis paub tseeb.

Ua kom zoo dua ntawm cov qauv tsim kom txuag tau sijhawm, nyiaj txiag, thiab emissions.

| Kev pabcuam | CNC Machining |

| Sheet Hlau Fabrication | |

| Tswj lub thawv | |

| Laser txiav Service | |

| Hlau Bracket | |

| Stamping qhov chaw | |

| Khoom siv | * Aluminium |

| * Hlau, Stainless hlau | |

| * Tooj, tooj dag | |

| * Yas | |

| * Tuag Casting | |

| Ua kom tiav | Sandblasting, Anodizing Xim, Blackenning, Zinc Nickl Plating, Polishing Thiab Txhuam, thiab lwm yam. |

| Cov cuab yeej tseem ceeb | CNC Machining Center (Milling), CNC Tshuab dhos, Griantry CNC Machining Center, thiab lwm yam. |

| Cylindrical Grinder Tshuab, Drilling Tshuab, Laser Tej Tshuab, thiab lwm yam. | |

| Bending Tshuab, Stamping Tshuab, Sand Blasting Tshuab, Hmoov Txheej Kab. | |

| Tube Laser Tej Tshuab, nplaim txiav tshuab, Robert Vuam caj npab, thiab lwm yam. | |

| Kev kos duab | Kauj ruam, Stp, Gis, Cad, Pdf, Dwg, Dxf Etc Los yog Samples. |

| Lub sij hawm xa tuaj | 5-30 Hnub nyob ntawm seb muaj pes tsawg |

| QC | ROSH, CE, ISO |

| Ua siab ntev | +/- 0.02mm ~ +/-0.05mm |

| Nto Roughness | Ra 0.6-3.2 |

Yam khoom

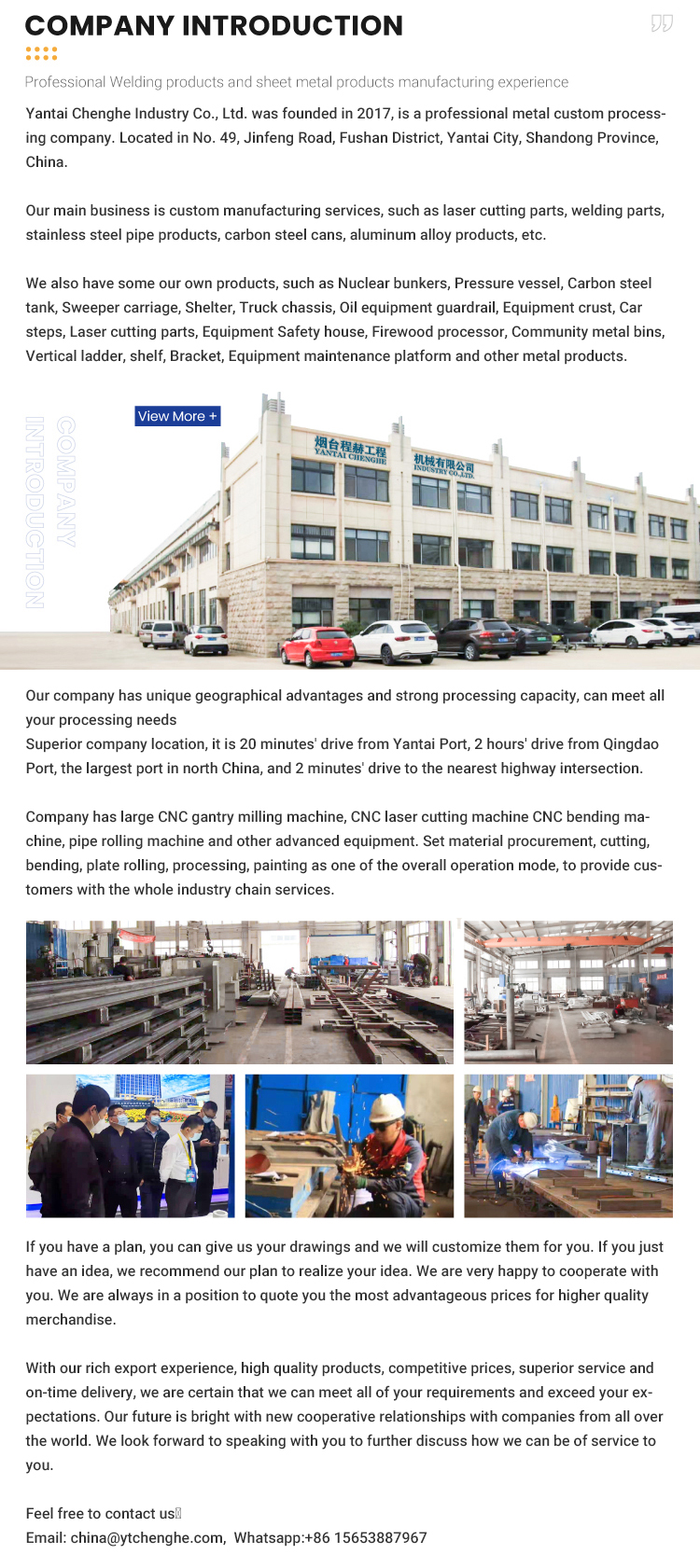

Lub tuam txhab muaj zog

FAQ